Alloy 25 - CuBe2 Alloy & Alloy M25 - CuBe2Pb - - ASNA 3417 – ASNA 3411 – ASNA 3400 - ASNA 6110

Bars and Wire

Origin

- United States

-

Description

Copper-beryllium alloys with about 2% beryllium cover a wide range of mechanical properties, from an unaged and ductile condition to aged conditions with high strengths in the range of hardened steels. The M25 grade, due to the controlled addition of lead, is suitable for free cutting while retaining the same mechanical properties as alloy 25. These alloys are produced and processed by Materion in the USA.

Stainless has a range of sizes and grades in stock to suit your processing requirements. This product can also be made to order or cut into slugs by our service centres.

Main applications

These copper alloys have very good corrosion resistance, low coefficients of friction and very high hardness for copper alloys. They are explosion-proof (no sparking), seizure resistant and can be heated up to about 250°C.

Connections: electrical contacts, relays.

Aeronautics: joint rings subject to high loads, screws, ball joint elements, hinge parts.

Other: oil research probes, connecting rod bearings, valve guides, clocks.

Metallurgy

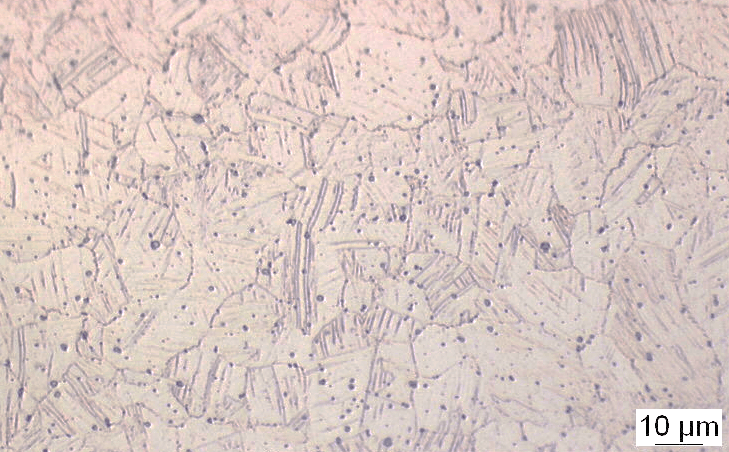

The M25 grade contains homogeneously distributed lead to improve the machinability of the material. The typical microstructure is shown below:

Machinability

Machinability

Beryllium is a chemical element, which can present health risks when inhaled, especially in the form of fine dust. Special precautions must be taken during processing which leads to the production of dust. Grinding should be carried out under heavy watering and welding (not recommended) should be carried out under effective suction. Welding is not recommended.

Heat treatments

Products supplied in the solution treated condition (condition A) or in the solution treated then cold worked condition (conditions 1/4H, 1/2H, 3/4H, H) can be treated by ageing at 315°C +/-5°C for a minimum of 2 hours in order to obtain maximum hardness. Overaging is also possible to reduce hardness in certain applications. Other grades (AT, HT, 1/2HT,…) are already aged and can be used without additional heat treatment.

Corrosion resistance

Alloys 25 and M25 are highly resistant to corrosion in marine environments. Hydrochloric and sulphuric acids can accelerate corrosion in the presence of oxidising impurities.

Standard Sizes

Round bars, wire and flats, annealed or cold worked – Hardened or ground surface.

Other formats: Tubes – Strips (see associated data sheets)

THE MAIN Copper Beryllium ALLOY GRADES

Copper Beryllium

ST25 – Cuivre-béryllium

STM25 – alliage M25

ST190 – alliage 190

ST290 – alliage 290

ST174 – alliage 174

ST3 – alliage 3

Copper alloys

ST360 – ALLIAGE 360 – Nickel Beryllium

UA11N

ST630-20AMS

UNS C 63020

ST955

UNS C 95510

UZ19A6

CuZn19Al6