ToughMet® 3 - CuNi15Sn8 alloy - C72900 - C96900 - ABS 5849 - ABS 5152

Origin

- United States

-

Description

Toughmet ® 3 is a beryllium-free copper alloy that hardens by spinodal decomposition during heat treatment. This alloy can be an alternative to CuBe2 as it combines high mechanical properties, high resistance to friction, seizure, wear and corrosion.

This alloy is produced and processed by Materion in the USA.

STAINLESS has a range of sizes and grades in stock to suit your application needs.

This product can also be custom made or cut into slugs by our service centres.

Main applications

ToughMet®3 has very good corrosion resistance, low coefficients of friction and very high hardness for a copper alloy. It is heat resistant up to 300°C depending on the condition.

Aeronautics: joint rings subject to high loads, screws, ball joint elements, hinge parts.

Others: oil research probes, connecting rod bearings, pins and ball joints for construction equipment.

Metallurgy

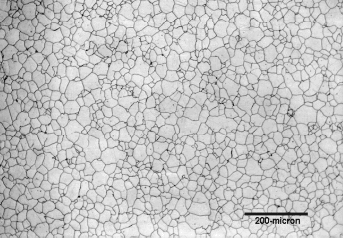

The grade is fine-grained and homogeneous in the AT and TS temper. The typical microstructure in the AT temper is shown below:

Machinability

ToughMet® 3 is less heat conductive than standard copper alloys, so it is advisable to use sufficient coolant to remove heat. A positive rake angle is strongly recommended.

Heat treatments

All products supplied in ToughMet®3 are already heat treated at the factory and can be used without additional heat treatment.

Corrosion resistance

ToughMet®3 alloy is highly resistant to corrosion in marine environments. It complies with NACE MR0175/ ISO 15156. The alloy has excellent resistance to pitting and is not susceptible to hydrogen embrittlement.

Standard Sizes

Round bars, tubes, wire and flat bars in treated condition – surface ground or peeled.

Other shapes: Coils

THE MAIN Copper Beryllium ALLOY GRADES

Copper Beryllium

ST25 – Cuivre-béryllium

STM25 – alliage M25

ST190 – alliage 190

ST290 – alliage 290

ST174 – alliage 174

ST3 – alliage 3

Copper alloys

ST360 – ALLIAGE 360 – Nickel Beryllium

UA11N

ST630-20AMS

UNS C 63020

ST955

UNS C 95510

UZ19A6

CuZn19Al6