M30NW - 1.4472 - ASTM F1586

Description

The 1.4472 grade has superior corrosion resistance and mechanical properties to the 1.4441 (316LVM) grade. The mastery of its EAF/AOD production method followed by ESR remelting gives it a high level of cleanliness and homogeneity, which are essential to guarantee high fatigue resistance and quality processing.

Stainless has a number of qualified European sources in stock as well as different formats or product states to suit your processing needs. This product can also be made to measure or cut into slabs by our service centres.

Each material is delivered with its producer’s certificate of origin to guarantee total transparency and traceability.

Main applications

Due to its recognised biocompatibility in the medical field, the grade is mainly used in the manufacture of implants obtained by forging and/or machining. The material is available in the annealed state but also in the hardened state for smaller dimensions.

Metallurgy

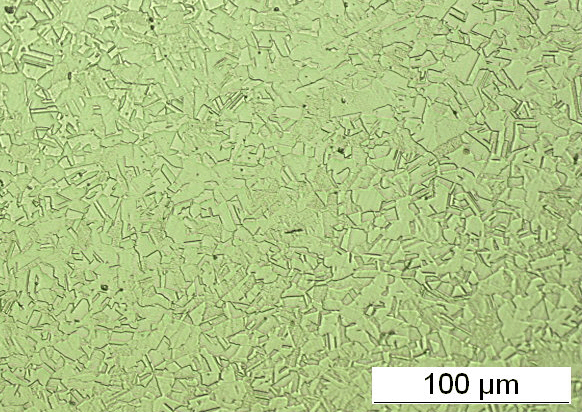

The elaboration processes associated with the transformation processes make it possible to obtain a homogeneous microstructure with a fine grain of at least index 5

The microstructure consists of austenitic grains and does not show delta ferrite or Chi phase under standard observation conditions (X 100).

Machinability

Forgeability

The grade can be hot forged in the temperature range 1000/1150°C.

Polishability

The high level of inclusionary cleanliness and the homogeneity of the microstructure of this grade allows optimum polishing.

Typical Heat Treatments

Annealing at 1050-1080°C followed by rapid quenching can be carried out after forging to restore corrosion resistance, but no heat treatment is used to harden the grade.

Corrosion resistance

The grade is highly resistant to general and pitting corrosion due to its high molybdenum and nitrogen content combined with its low inclusion rate.

Standard Sizes

Round bars annealed, medium-hard or hard depending on the diameter – Surface ground or peeled.

Flat bars made to measure in the annealed condition (consult us)

Other formats: please contact us

The above information is given as an indication. They may vary depending on the diameter or condition of the alloys. For more detailed information or advice, please contact us.

Stainless has a wide range of stainless steels from the world's leading producers.

Available formats: Strips, tubes, bars, wires, flat bars, forged blocks, powders

Other formats are available from stock or on order. Contact us.

Austenitic stainless steels

316 – 1.4401

304L- 1.4307

1.4435

A286 – 1.4980

Nitronic®50 – 1.3964

Nitronic®60

Martensitic steels with structural hardening (type PH)

17-7PH – 1.4568

Remelted austenitic stainless steels for prostheses and implants

M30NW® – 1.4472

316LVM – 1.4441

Biodur® 108