Cobalt-based alloy M64BC® - CoCr28Mo6 – UNS R31537

Origin

- Europe

-

or

or - United States

-

Description

The cobalt-based alloy CoCr28Mo6 has excellent corrosion resistance and very high mechanical properties. The mastery of its VIM production method followed by ESR remelting gives it a high level of cleanliness and homogeneity, which are essential to guarantee high fatigue resistance and quality processing.

Stainless has a number of qualified European and American sources in stock and a range of diameters to suit your processing requirements. This product can also be made to measure or cut into pieces by our service centres.

Each material is delivered with its producer’s certificate of origin in order to guarantee total transparency and complete traceability.

Main applications

Due to its recognised biocompatibility in the medical field, the grade is mainly used in the manufacture of implants (prostheses, spine rods, etc.) obtained by forging and/or machining. The material is available in the warm worked temper for all diameters.

Metallurgy

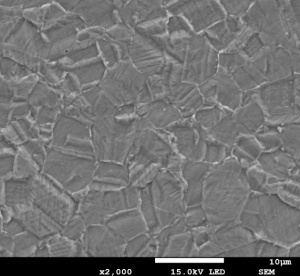

The elaboration processes associated with the transformation processes make it possible to obtain a homogeneous microstructure with a fine grain of at least index 5. See micrograph below:

Machinability

Forgeability/Usability

The grade can be hot forged in the 1100/1200°C temperature range. Machining of this grade requires suitable equipment and tools.

Polishability

The high level of inclusionary cleanliness and the homogeneity of the microstructure of this grade allows for optimum polishing.

Heat Treatments

Annealing can be carried out from 950°C to soften the grade. However, this treatment must remain under control so as not to degrade the quality of the microstructure and the grain size. No heat treatment can increase the hardness.

Corrosion resistance

The grade is highly resistant to general and pitting corrosion due to its high chromium and molybdenum content and low inclusion rate.

Standard Sizes

3m round bars in the warm-worked condition – surface ground or peeled.

Taylor made Flat bars in the warm-worked temper (consult us)