Grade 5 Titanium - TA6V - TiAl6V4 - 3.7165

Description

TA6V alloy (Grade 5 Titanium) has low density, high corrosion resistance and high mechanical properties. This grade is the most common of the titanium alloys. It differs from grade 23 (or TA6V4ELI) by its higher oxygen content.

Stainless has a number of qualified sources in stock as well as different diameters to meet your processing needs. This product can also be made to measure or cut into slugs by our service centres.

Each material is delivered with its producer’s certificate of origin in order to guarantee total transparency and complete traceability.

Main applications

Grade 5 Titanium is used in particular in the manufacture of structural and engine parts, but also in aeronautical fasteners. TA6V4 is highly resistant to corrosion, which makes it suitable for use in marine environments, the surface treatment industry and the deck fittings industry. The material is available mainly in the annealed state but can be treated (STA) with a temperature resistance close to 350°C.

Metallurgy

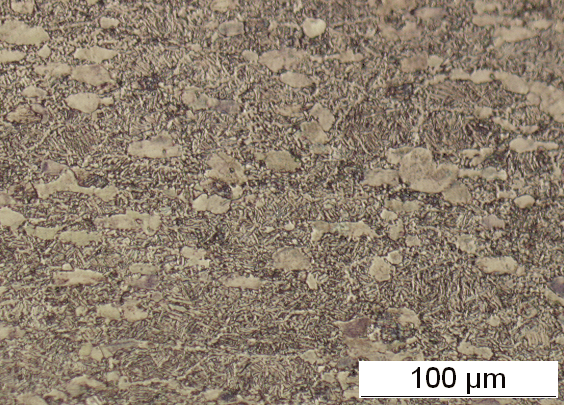

Grade 5 Titanium can be produced with one or more VAR denials depending on the criticality of the applications. The elaboration processes associated with the transformation processes make it possible to obtain a homogeneous alpha/beta microstructure with a structure type A1 to A9. See micrograph below:

Machinability

Forgeability/Usability

The grade can be hot forged below beta transus (<950°C). Machining of this grade requires sufficient coolant to limit heating. The grade is difficult to work cold because of seizure.

Polishability

The high level of inclusionary cleanliness and the homogeneity of the microstructure of this grade allows optimum polishing, particularly if the microstructure is fine.

Heat treatments

Annealing can be carried out from 700°C after forging. However, this treatment must remain under control so as not to degrade the quality of the microstructure. After annealing, the oxidised surface is removed mechanically or chemically to remove the contamination layer (alpha case).

A heat treatment of quenching followed by ageing (STA) is possible on this grade depending on the dimensions in order to increase the mechanical properties up to about 1100MPa.

Corrosion resistance

Grade 5 Titanium is highly resistant to general and pitting corrosion. Chlorinated solvents should be avoided. Titanium is also susceptible to hydrogen embrittlement, so it is important to limit any hydrogen input during heat treatment or chemical pickling processes.

Standard Sizes

3m round bars in the annealed condition – Surface ground or peeled

Flat bars made to measure or forged blocks in the annealed state (consult us)

Powders – Sheets – Wires