Ti 6246 – AMS 4981

Description

Titanium alloy Ti6246 has even higher mechanical properties than Ti6242 and also creep resistance up to about 530°C. Its low density combined with its high level of mechanical strength also gives it an advantage in moving and high temperature applications.

Stainless has a number of qualified sources in stock and different diameters to suit your application needs. This product can also be custom made or cut into slugs by our service centres. Each material is delivered with its producer’s certificate of origin in order to guarantee you total transparency and complete traceability.

Main applications

Applications include turbine parts, discs and other hot-worked components in the aerospace, industrial and motor racing sectors.

Metallurgy

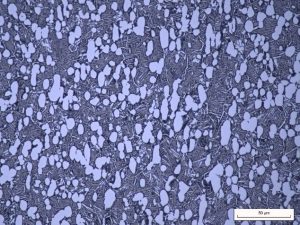

The grade can be produced with several VAR rejections depending on the criticality of the applications; at least one VAR remelting is mandatory for this grade. The manufacturing processes associated with the transformation processes make it possible to obtain a homogeneous alpha/beta microstructure without a continuous alpha phase network at the grain boundaries. The micrograph below illustrates the typical microstructure:

Machinability

Forgeability/Usability

The grade can be hot forged, the beta transus is close to 940°C. Machining of this grade requires sufficient watering to limit heating. The grade remains very difficult to weld.

Heat treatments

The grade is offered as standard in a pre-treated STA version (according to AMS 4981). An annealed condition can be offered on request and can be followed by an STA treatment to optimise the mechanical properties.

Corrosion resistance

The grade is highly resistant to general corrosion and also to pitting. Chlorinated solvents should be avoided. Titanium is also susceptible to hydrogen embrittlement, so it is important to limit any hydrogen input during the processing.

Standard Sizes

3m round bars in STA condition – Surface ground or peeled

Other formats (please consult us)